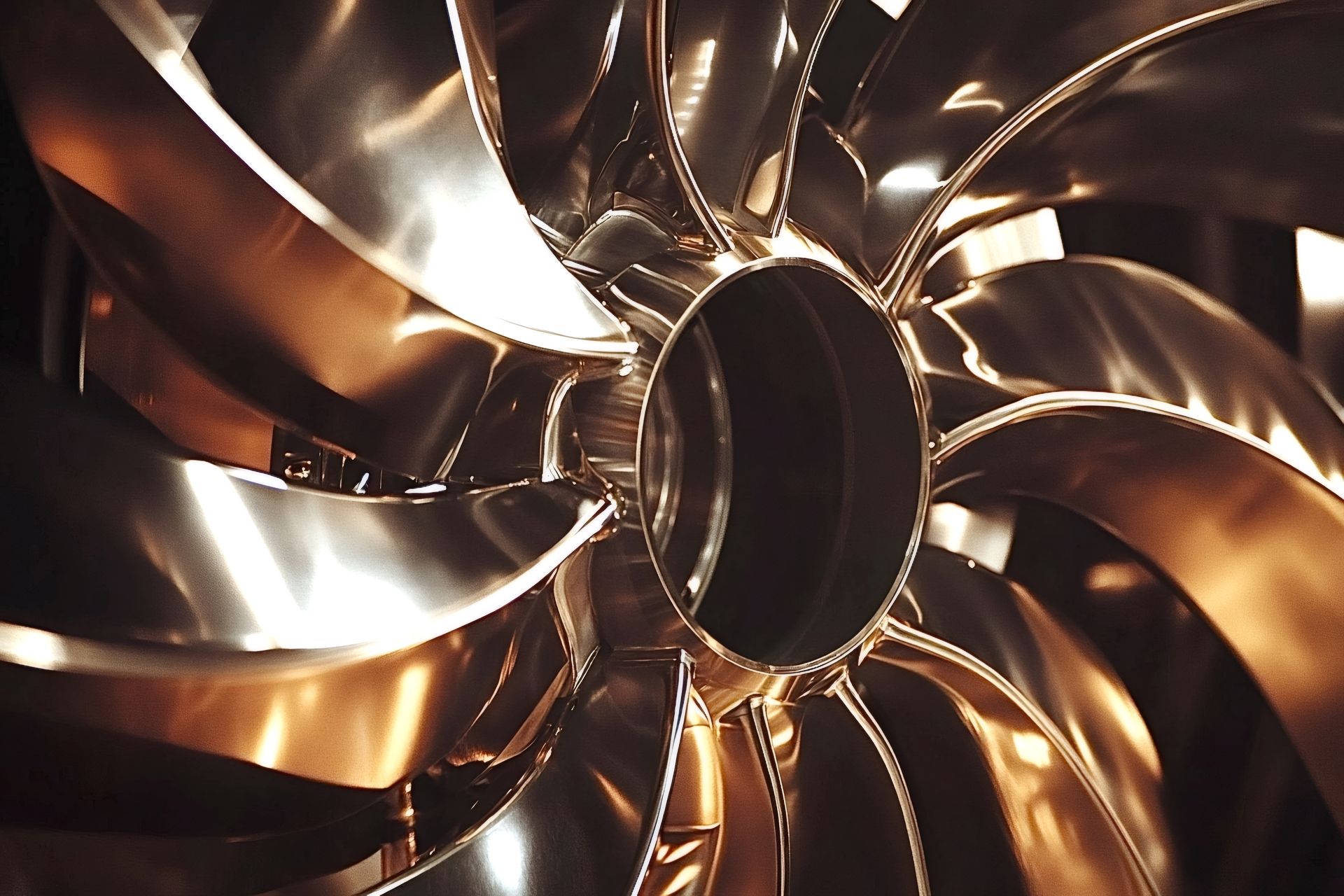

Industrial turbines are essential rotating machines that convert fluid energy into mechanical power for various industrial applications. These machines serve critical roles in power generation, oil and gas facilities, chemical processing plants, and manufacturing operations worldwide. Modern turbines utilize advanced materials and engineering designs to handle high temperatures, pressures, and continuous operation demands. The basic principle involves directing high-velocity fluid flow against specially designed rotor blades to generate rotational motion and extract energy efficiently.

Gas turbines are the most common type in industrial settings, featuring three main components: an air compressor, combustion chamber, and power turbine section. These units can operate on natural gas, diesel, or other fuels, achieving thermal efficiencies of 35-45% in standard configurations. When combined with steam cycles, efficiency can exceed 60%. Gas turbines range from small 1MW units for backup power to large 300MW+ machines for utility-scale generation. They offer quick startup capabilities, reliable operation, and relatively low maintenance requirements compared to other power generation technologies.

Steam turbines remain vital for power plants and industrial processes requiring steam for heating or manufacturing. These machines extract energy from high-pressure steam, expanding it through multiple stages to maximize power output. Steam turbines can achieve very high efficiencies (over 90%) and provide excellent load-following capabilities. They’re particularly valuable in combined heat and power applications where process steam is required alongside electricity generation. Modern steam turbines feature advanced blade designs, improved sealing systems, and sophisticated control systems for optimal performance.

Specialized turbine applications include expansion turbines for energy recovery, micro-turbines for distributed power, and process gas turbines for specific industrial needs. Expansion turbines capture energy from high-pressure waste streams in chemical plants, reducing energy costs significantly. Micro-turbines (30-350kW) offer clean, efficient power for smaller facilities and remote locations. Process gas turbines drive compressors for pipeline applications and provide mechanical power for various industrial equipment.

When selecting industrial turbines, key factors include initial cost, operating efficiency, maintenance requirements, reliability, and service support. Modern turbine packages include complete auxiliary systems such as control panels, lubrication systems, and safety equipment. Maintenance programs typically involve scheduled inspections, component replacement, and performance monitoring to ensure optimal operation. Leading suppliers provide comprehensive service support, spare parts availability, and technical assistance to maximize equipment lifespan and operational efficiency for industrial customers.